AUTOMOTIVE SPICE®

June 28, 2018

Cyber Security ISO 21434

June 28, 2018

Functional Safety “absence of unreasonable risk due to hazards caused by malfunctioning behaviour of E/E systems"

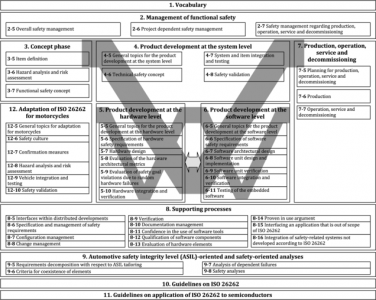

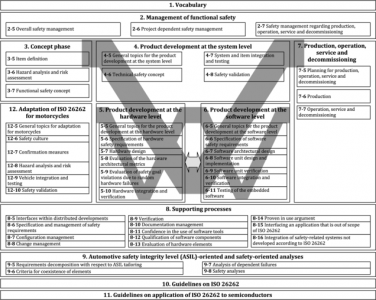

In recent years, cars have become more and more complex, intelligent. With multiple features on today’s automobiles that are electronically controlled has resulted in various advantages as well as contributed to additional risk. With complex software and hardware being part of the automotive systems, it is become important to recognize any potential risks of hardware or software related failures. The results of such failures could result in severe injury or possible loss of life. The International Organization for Standardization (ISO) recognized this need and published the ISO 26262 standard to help ensure functional safety of electrical and electronic systems in road vehicles.

ISO 26262 is an international standard for functional safety in automotive development. ISO 26262 defines functional safety for automotive equipment applicable throughout the lifecycle of all automotive electronic and electrical safety-related systems. The standard applies to electrical and electronic systems consisting of hardware and software components in vehicles. Functional safety features form an integral part of each automotive product development phase, ranging from the specification, to design, implementation, integration, verification, validation, and production release. ISO 26262 defines requirements to be met by the safety relevant function of the system as well as by processes, methods and tools which are used within the development process.

Using ISO 26262 to evaluate the safety of your vehicle’s electrical and electronic components provides multiple benefits to automotive original equipment manufacturers (OEMs) and suppliers. Though not a regulation, ISO 2626 has been implemented by automotive industry to develop safety products safely.

QMGC provides functional safety (ISO 26262) Training, Gap Analysis and Consulting services involving experts.